4, nll9027

[45] Septemba 5, 1978

Bottomley

[54]ELECTROMAGNETIC APPARATUS

[76] Onye na-emepụta ihe:Alan Stuart Bottomley,69 Queen St.,

Sandy Bay, Tasmania, 7005,

Ọstrelia

[21] App.Mba:657»243

[22] Ederede:Ọnwa Abụọ 11,1976

[30]Data mkpa ngwa nke mba ofesi

Febụwarị 12, 1975 [AU] Australia PC0564

Ọkt. 20, 1975 [AU] Australia PC3629

| [51] | Int.Cl.2 | B21D 11/04 |

| [52] | US Cl | 72/320; 72/457 |

| [58] | Mpaghara nke ọchụchọ | 72/319, 320, 321, 457, |

| 72/461;269/8;29/DIG.95, DIG.105 | ||

| [56] | Ntụaka akpọpụtara | |

| AKWỤKWỌ PATENT US | ||

| 1,595,691 8/1926 Simmons .. | 269/8 X | |

| 2,302,958 11/1942 Jensen ...... | 72/319 | |

| 2,429,387 10/1947 Buchheim | 72/461 | |

| 3,439,416 4/1969 Yando …… | 269/8 X | |

| 3,855,840 12/1974 Kawano ... | 72/418 | |

Onye nyocha nke izizi—Leon Gilden

Onye ọka iwu, onye nnọchi anya ma ọ bụ ụlọ ọrụ- Murray na Whisenhunt

[57]ABSTRACT

Ihe mepụtara na-enye ngwá ọrụ emegharịrị karịsịa maka ọla arụ ọrụ.Ngwá ọrụ ahụ nwere eriri elektrọn, okporo osisi a na-emegharị ka ọ bụrụ magnetized site na eriri igwe, yana elu ọrụ nwere ike ime n'akụkụ okporo osisi na arụ ọrụ a na-eji etinye ike na-ehulata na mpempe ọrụ ejiri ike ndọta jide n'osisi ahụ.

Enwere ike ịnye ndị na-eche nche ka ọ dọọrọ mmasị na mkpanaka iji jide akụkụ ọrụ ahụ.Enwere ike itinye agụba ma ọ bụ ọkpọ.

Elu ọrụ nwere ike ịbụ akụkụ nke ahụ nke, mgbe ebupụrụ ya n'ọnọdụ izu ike, na-eme ka eriri eriri ahụ nwee ume na nke ike magnetik na-agba ya ume ịlaghachi n'ọnọdụ izu ike ahụ iji wepụ ike eriri igwe ahụ.

A na-ejikọta ahụ ahụ na okporo osisi site na mgbanaka nke na-adịghị arụ ọrụ n'elu ụgbọ elu ka ọ ghara igbochi ígwè na-ehulata.

Ngwa nwere ike iji magnetik jide onwe ya na bench.

Ngwá ọrụ ahụ nwere ike ịnwe sekit eletriki nwere ike ịmepụta DC maka njide magnetik ma ọ bụ AC ka e wee jiri ngwá ọrụ ahụ mee ihe dị ka demagnetizer.

18 na-ekwu, 10 Eserese Ihe osise

4

3

Patent US

Ọnwa Itolu 5, 1978

Mpempe akwụkwọ 4 nke 4

4,111,027

ELECTROMAGNETIC APPARATUS

ndabere nke ihe mepụtara

OGE NKE NKWUO

Ihe mepụtara a metụtara ngwa elektrọnik.N'otu akụkụ nke mmepụta ihe a metụtara ngwa ọrụ.N'akụkụ ka ukwuu nke a mepụtara na-emetụta ngwa ọrụ nke enwere ike iji na-ehulata, mpịakọta na imepụta akwụkwọ mpempe akwụkwọ na nke, mgbe emezigharịrị nke ọma, enwere ike iji bee na ịkụtu ihe.

Ihe mepụtara nwere ngwa pụrụ iche na nchikota, mpịachi na ịkpụpụta metal mpempe akwụkwọ dị ka igwe anaghị agba nchara, aluminom, igwe anaghị agba nchara, mpempe zinc na galva nized iron mana ejedebeghị iji ya mee ihe.

kwadoro na ezumike kwuru na ebe a na-ekwu na ozu n'ọnọdụ siri ike ọ dịghị akụkụ nke okporo osisi ahụ, onye òtù ahụ kwuru ma ọ bụ kwuru ọrụ ahụ n'otu akụkụ nke ụgbọ elu ahụ.Ọtụtụ ọkachamma na e nwere hinge pin ebu site na okporo osisi na 5 nwere a ọkara okirikiri convexity transverse kwuru axis na natara na a ezumike na kwuru na onye na-enwe a ọkara okirikiri concave udi na ebe substantially ọ dịghị akụkụ nke kwuru pin oru ngo na kwuru otu akụkụ. nke kwuru ụgbọ elu.Ngwá ọrụ nwere ike ịgụnye a otutu nke ndị dị otú ahụ hinges na ọ bụ

1. na-achọsi ike na opekata mpe otu n'ime ihe ndị a na-ekwu bụ oghere site na nsọtụ nke ahụ nke mere na a na-ekesa ibu karịa ebe ahụ.

A ga-egosipụta ihe emepụtapụtara ugbu a site na ihe atụ na-enweghị oke site na enyemaka nke ndị na-eso ya.15eserese.

Nchịkọta nke ihe mepụtara

Ihe nchoputa a na-enye ngwa nke nwere eriri igwe magnetik, okporo osisi emegharịrị ka ọ bụrụ magnetized site na eriri igwe, yana elu ọrụ nwere ike ime n'ihe gbasara20 okporo osisi na onye na-arụ ọrụ iji tinye ike na-ehulata na mpempe ọrụ ejiri ike magnetik jide n'osisi ahụ.

Nkọwa nke akụkụ ndị ahọpụtara

The ngwá ọrụ ọkachamma na-agụnye onye nche na-emegharị ka 25 dọtara na okporo osisi mgbe okporo osisi magnetized na jide ọrụ ibe n'ebe ahụ.N'ozuzu, a ga-eji ọnụ ọgụgụ nke ndị nche dị otú ahụ mee ihe ma bụrụ nke dị iche iche na / ma ọ bụ ọdịdị.

N'otu aka ahụ, ngwá ọrụ ahụ na-agụnye mgba ọkụ pụtara 30 na elu ọrụ bụ elu nke anụ ahụ bụ nke nwere ike ime n'akụkụ okporo osisi site na ọnọdụ mbụ nke a na-eme ka mgba ọkụ ahụ pụta ìhè iji mee ka eriri ahụ na-eme ka ọ bụrụ ọnọdụ nke abụọ. nke ihe ngbanwe pụtara na-eme ka ọ na-eme ka ikuku dị ike.N'ikpeazụ a ọ dị mma 35 na ahụ ahụ bụ ihe mejupụtara ferromagnetic ma tinye ya n'osisi ebe a ga-esi na-agbanye ike nke eriri igwe site na ọnọdụ nke abụọ gaa n'ọnọdụ mbụ.

A na-ahọrọkwa ya na okporo osisi ahụ na-agụnye mbara ala 40 nke nwere ọnụ na ebe elu ọrụ dị na-eme atụmatụ ma na-emegharị ya ka ọ bụrụ ihe dị ka axis ọ dịkarịa ala na-ejikọta ọnụ na nsọtụ ahụ.

Ọ bụrụ na-ịchọrọ, onye nche nwere ike inye ụzọ emegharị ka banye workpiece na mma nke 45 nche na okporo osisi.Nke ahụ pụtara nwere ike ịbụ mbelata ma ọ bụ nwere ike ịbụ ọkpọ.N'ihe gbasara ntụmadị, ọ ga-abụ ihe kwesịrị ekwesị na ngwa ahụ gụnyekwara nwa nwanyị anwụ ka o jiri ntụ ntụ rie nri.

Ngwá ọrụ a nwere n'ụzọ eletriki gụnyere ihe nrụzi 50 emeziri iji nye DC ugbu a na eriri igwe yana n'ihu gụnyere mgba ọkụ emegharịrị iji jikọọ eriri igwe na nhọrọ na rectifier ma ọ bụ na ọkọnọ AC.

Ngwá ọrụ ahụ nwere ike jikọta ya na nkwado maka ngwá ọrụ 55;nkwado nke nwere ihe ferromagnetic nke akụrụngwa nwere ike itinye onwe ya site na mma ndọta n'ime ya.

N'otu aka ahụ, ogwe osisi ahụ na-agụnye mbara ala nke nwere ọnụ ọnụ, elu ọrụ ahụ bụ elu elu 60 nke anụ ahụ nke, n'otu ọnọdụ nke ahụ ahụ, na-edina ma ọ dịkarịa ala n'otu ụgbọ elu ahụ nke mbụ e kwuru n'elu elu. , kwuru na ahu bụ pivotable banyere ihe axis dịkarịa ala substantially co-omume na kwuru n'ọnụ site a hinge mejupụtara ezumike na kwuru 65 osisi nwere a ọkara okirikiri concave udi transverse kwuru axis na a so na-ebu site kwuru ahu nwere ọkara. - okirikiri convexity gafere na axis kwuru wee tụgharịa ọzọ.

Nkọwa dị mkpirikpi nke echiche nke

Ihe osise

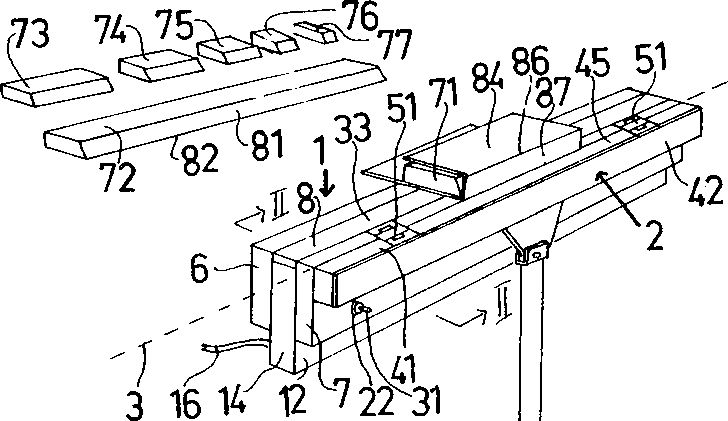

FIG.1 bụ nleba anya n'echiche nke ngwá ọrụ dịka ihe mepụtara a si dị,

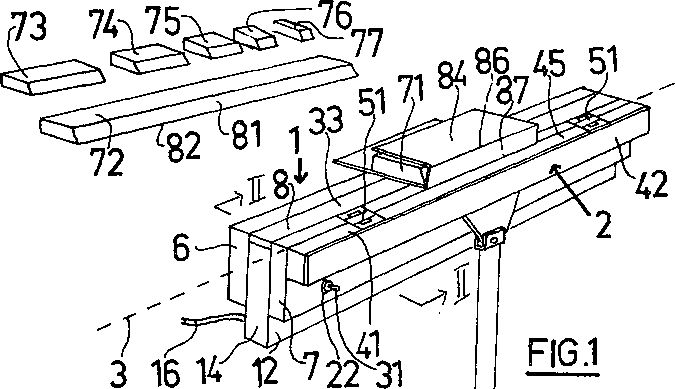

FIG.2 bụ akụkụ obe na ahịrị II-II na FIG.1,

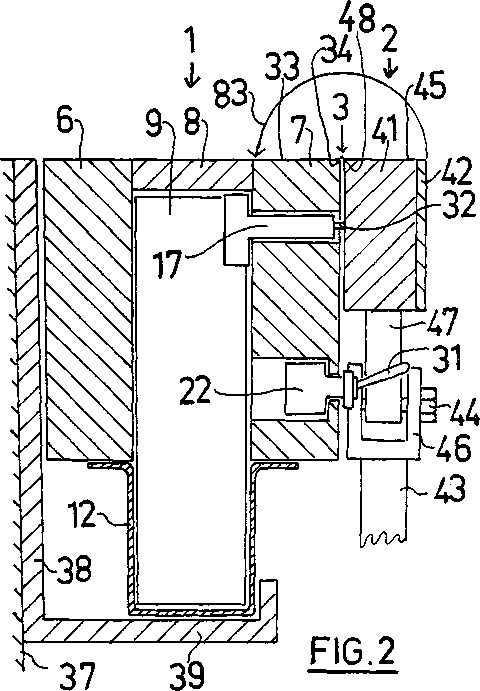

FIG.3 bụ amụma oblique nke akụkụ nke akụrụngwa,

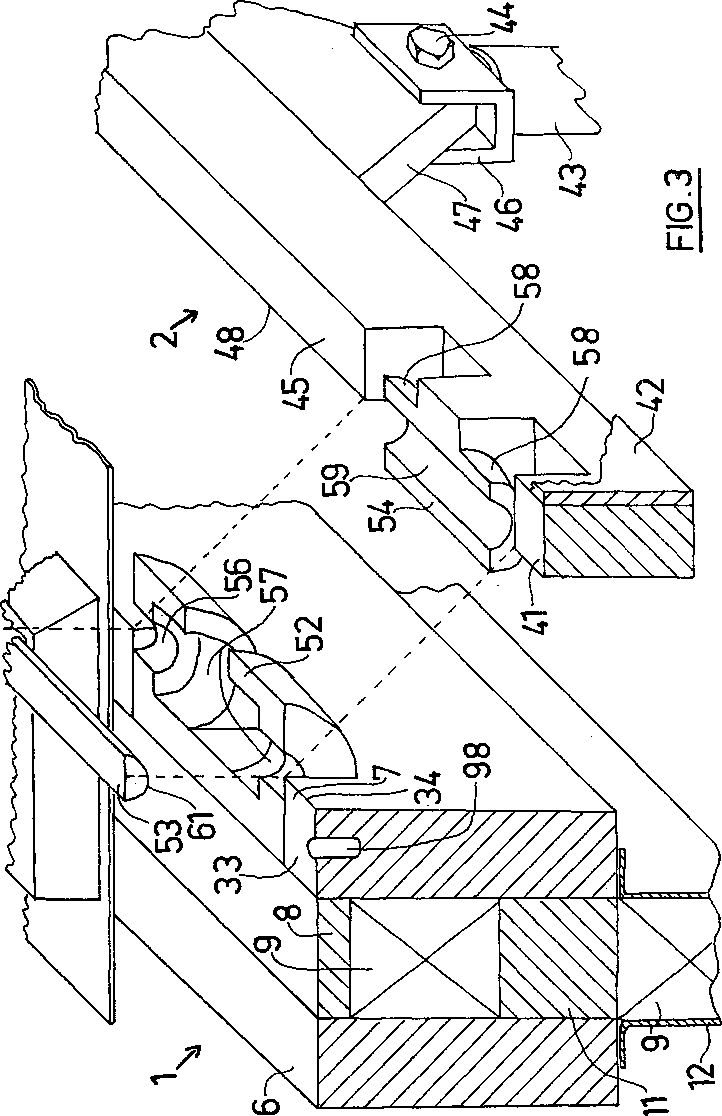

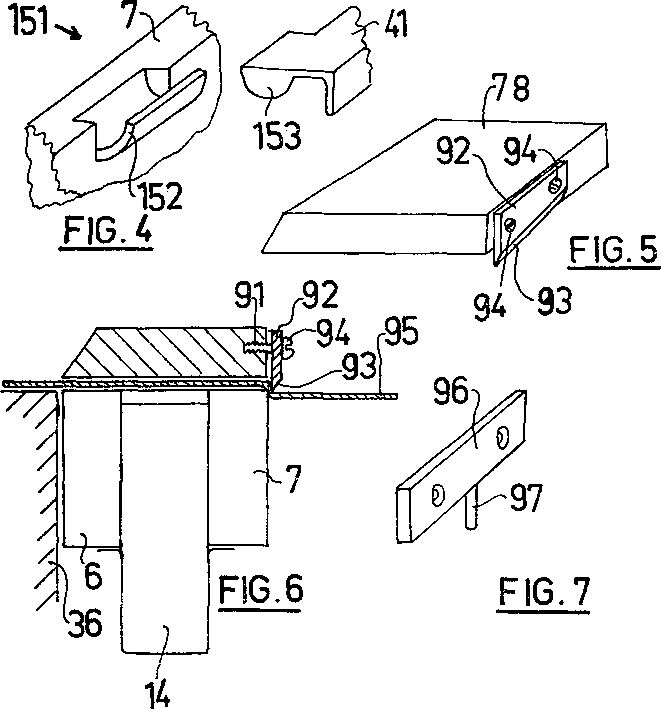

FIG.4 bụ nlele anya na-egosi mgbanwe,

FIG.5 bụ nlele anya na-egosi ngwaọrụ eji eji ngwa,

FIG.6 bụ njedebe njedebe nke ngwá ọrụ ma na-egosi de vice nke FIG.5 na-eji,

FIG.7 bụ nlele anya na-egosi ngwaọrụ ọzọ maka iji ngwaọrụ ahụ,

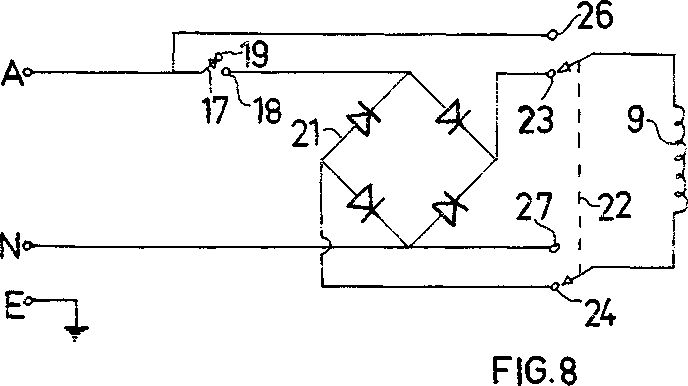

FIG.8 bụ eserese schematic nke sekit eletriki nke ngwaọrụ, na

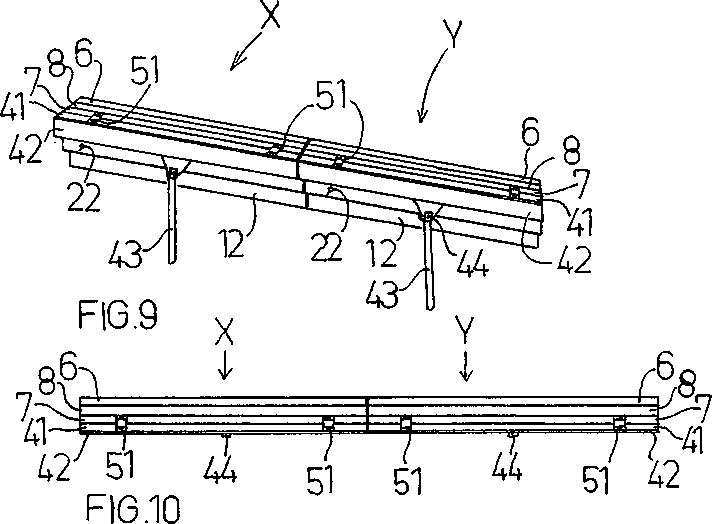

FIG.9 bụ nleba anya n'echiche nke abụọ n'ime ngwaọrụ ndị ejikọtara na njedebe na njedebe, na

FIG.10 bụ nleba anya atụmatụ nke ngwaọrụ ejikọtara ọnụ nke FIG.9.

Nkọwa zuru ezu

Ngwá ọrụ egosiri na FIGS.1-3 nwere elongate electromagnet nke egosipụtara n'ozuzu site na 1 yana indi nke a na-eme n'ozuzu ya site na 2 bụ nke nwere ike ime n'ihe gbasara electromagnet 1 gbasara axis 3.

Eletrọmagnetị 1 nwere ogwe azụ 6 na ogwe ihu 7, ma ihe ferromagnetic.The elec tromagnet 1 n'ihu na-agụnye a spacer 8 nke na-abụghị magnetik ihe dị ka aluminium, a eriri igwe 9, a isi 11, a eriri igwe cover 12, na njedebe na-ekpuchi 14. Ndị mkpuchi na- prefera bly mmasị site kposara (egosighi).A na-emekwa isi 11 nke ihe ferromagnetic na eriri igwe 9 bụ waya na-efegharị, dị ka waya ọla kọpa 22 guage, ka ọ bụrụ ụdị oval n'ozuzu nke dị gburugburu isi.

11.

Ogwe 6 na 7 na isi 11 na-adaba adaba na bolts (anaghị egosi ya) nke a ga-ejikwa eriri igwe 9.

Ọ na-ahọrọ iji dị ka ferromagnetic ihe a materiid nwere akwa saturation magnetisation dị ka ígwè.

Igwe elektrọn 1 n'ihu gụnyere ngwa eletriki nke nwere isi ihe na-enye ụzọ 16 nke ejikọrọ na sekit eletriki nke electromagnet maka ịnye AC isi ugbu a.

E gosipụtara sekit eletrik na FIG.8 ma a ga-amata na a na-ejikọta isi ihe na-enye ụzọ na-arụ ọrụ "A", na-anọpụ iche "N" na ụwa (ala)UE *** njedebe ya.

Igwe ọkụ eletrik na-agụnye otu mgba ọkụ 17 nke a na-ahọrọ na-agbanwe na njedebe 18 ma ọ bụ 19, ihe ngbanwe 21, mgba ọkụ okpukpu abụọ 22 nke bụ nhọrọ.

na-agbanwe nke ọma gaa na ọdụ 23 na 24 ma ọ bụ 26 na 27 na eriri igwe 9.

Mgbe mgbanwe 17 na-agbanye na, n'otu n'otu, ter minals 18 ma ọ bụ 19, ugbu a, ma ọ bụ na-adịghị ugbu a, ga-asọba na rectifier 21 ma ọ bụrụhaala na mgbanwe ahụ 22 na-agbanye na 5 ọnụ 23 na 24, eriri igwe 9 ga-abụ DC ume na ga mee ka okporo osisi 6 na 7 bụrụ magnetized iji dọta ihe ferromagnetic n'ime ya.

Mgbe mgbanwe 22 na-agbanye na njedebe 26 na 27 a ga-agafe 21 rectifier na mgba ọkụ 17 na 10 coil 9 ga-enwe ike AC na electromagnet 1 nwere ike iji dị ka demagnetizer maka ngwá ọrụ ma ọ bụ ihe ndị ọzọ.

A na-edobe ngwa eletrik n'ime magnet electro n'ọnọdụ ọ bụla dị mma dị ka n'azụ otu mkpuchi njedebe 14. Njikọ eletrik nke 15 switches 17 na 22teriri igwe 9 na ụzọ 16, na rectifier 21 egosighi na FIGS.1-3.

Enyere mgba ọkụ 22 na onye na-arụ ọrụ ntụgharị 31 nke na-achọsi ike na-arụ ọrụ site na mkpanaka 7 dị n'okpuru ahụ 2 dị ka egosiri na FIG.2 na mgba ọkụ 17 bụ pro- 20 vided na onye ọrụ na-akwụghachi ụgwọ n'ahịrị 32 nke na-achọsi ike na-arụ ọrụ site na okporo osisi 7 na mpaghara ahụ 2 dị ka egosiri na FIG.2. Onye ọrụ 31 na-arụ ọrụ na-arụ ọrụ na onye ọrụ 32 na-arụ ọrụ dị ka akọwara n'okpuru.25

Ekwesiri ighota na electromagnet 1 nwere atụmatụ elu elu 33 nakwa na nsọtụ 34 nke okporo osisi 7 na-ejikọta ya na axis 3.

A na-etinye electromagnet 1 nke ọma na bench site na bolts (egosighi ya) gafere site na 30 okporo osisi 6 na 7 na isi 11 ma nwee ike itinye ya na elu elu nke bench 36 dị ka egosiri na FIG.6.

Otú ọ dị, ebe ọ bụ na electromagnet 1 ga-emepụta ihe ndọta siri ike, ọ nwere ike ibugharị 35 site n'otu ebe gaa n'otu ebe ma nwee ike itinye magnetik n'onwe ya na nkwado.N'akụkụ a, a na-ezo aka na FIG.2 ebe nkwado 37 nwere bracket ferromagnetic 38 etinyere ya.Eletrọmagnetị ahụ nwere ike iji magnetik tinye onwe ya na bracket 38 mana maka ebumnuche nkwado, 40 karịsịa mgbe eriri igwe 9 nke electromagnet adịghị enye ume DC, bracket 38 nwere akụkụ 39 nwere ike ịkwado electromagnet site n'okpuru.

The ahu 2 comprises a ekwe doo 41 na-enwe a planar elu elu 45, a cover strip 42 nke edobere 45 ka doo 41 site kposara (egosighi) na a aka 43. The aka 43 na pivotally mmasị na doo 41 via bolt. 44 na yok 46 na tang 47. A na-eme ka aka 43 na-atụgharị anya n'ihe gbasara osisi 41 nke mere na ọ nwere ike ịtọ ya na ya ka ngwá ọrụ ahụ dị na kọmpat 50 apịaji ọnọdụ maka nchekwa ma ọ bụ njem.

A na-ejikọta osisi 2 na okporo osisi 7 site na hinges 51. Ndị hinges 51 bụ otu ihe nrụpụta nke mere na elu 33 na 45 na-edina n'otu ụgbọ elu n'otu ọnọdụ nke ahụ 2 (ọnọdụ egosiri 55 na FIGS. .1 na 2), nke mere na na kwuru otu ọnọdụ ọ dịghị òkè nke hinges 51 oru ngo n'elu kwuru ụgbọ elu na nke mere na axis nke pivotting, 3, bụ substantially na kwuru ụgbọ elu na substantially co-omume na nsọtụ 34 na nakwa ihu 48. nke ọkụ 41.60

The hinges 51 tinyekwara recesses 56 maka ịnata nsọtụ nke pin 53 na ọ ga-amarakwa na fbr mmetụta kasị mma ọ na-ahọrọ na nsọtụ nke pin 53 ga-echekwara na okporo osisi 7 na ndị recesses 56 site ịgbado ọkụ ma ọ bụ ihe ọ bụla ọzọ. adabara pụtara dị ka kposara.65

Iko 52 nwere akụkụ concave nke ọkara cylindrical 57 fbr na-anata akụkụ akụkụ cylindrical convex 58 nke shells 54. The shells 54 have semi-cylindrical concave surfaces 59 fbr co-operating with the semi-cylindrical convex surface 61 of the pins 53 .

Ya mere, radially, hinges 51 nke ọ bụla nwere iko 52, elu 57 na 58, shei 54, elu 59 na 61 na pin 53.

Ogologo oge, hinges 51 nke ọ bụla nwere akụkụ nke iko 52sshei 54 na akụkụ nke ọzọ nke iko 52 na ọ bụ karịsịa ka a ga-ahụ na akụkụ nke iko 52 na shells 54 nwere ike ọzọ tinyere dum ogologo osisi 7 na doo 41 ma ọ bụ nwere ike ọzọ na ịgbatị a ukwuu ogologo karịa gosiri na FIG.3.

A ga-eji electromagnet 1 na ahụ 2 mee ihe na onye na-eche nche yana ndị na-echekwa 71-77 na-egosi na FIG.1. Ndị na-echekwa ihe niile bụ ferromagnetic ma terial, na-abụkarị akụkụ anọ ma nwee ihu mkpọda dị ka elu 81.

Ọ bụ n'ihu ka a mara na na ọnọdụ egosiri na FIGS.1 na 2 ahụ 2 na-eme ka onye ọrụ 32 nke mgba ọkụ 17 daa mbà n'obi nke mere na mgba ọkụ 17 ga-agbanye na njedebe 19 ma na na pivotting nke ahụ 2 banyere axis 3 a ga-ahapụ onye ọrụ 32 ka ịgbanwee 17 gaa na njedebe. 18. Ka na-aga n'ihu, a na-eji ihe ferromagnetic eme beam 41 nke mere na mgbe eriri igwe 9 bụ DC na-enye ike ọ ga-abụ magnetically dabere n'ọnọdụ ahụ iji mee ka onye ọrụ 32 daa mbà ma si otú ahụ wepụ ike mkpuchi 9.

Iji jiri ngwá ọrụ ahụ dị ka ihe mgbakwasị ígwè, a na-etinye mpempe akwụkwọ n'elu 33 na 45, mgbe ahụ, a na-ahọrọ onye na-elekọta ogologo oge kwesịrị ekwesị ma tinye ya n'elu mpempe akwụkwọ ahụ na nke mere na ọnụ ya, dị ka nsọtụ 82. n'ahịrị dị na mpempe akwụkwọ nke a ga-ehulata na ya na axis 3.

A na-agbanye mgba ọkụ 22 na njedebe 23 na 24 ma ọ bụrụ na ọ bụghị na ọnọdụ ahụ ma a na-emegharị 43 aka ka ọ gbanye ọkụ 41 na ntụziaka nke akụ 83. Ntugharị nke ọkụ 41 ga-ahapụ onye ọrụ 32, eriri igwe 9 ga-adị. DC na-eme ka ọ dị ike ma na-adọta ma ọ dịkarịa ala onye na-elekọta ya na ogwe osisi 6 na 7 na mpempe akwụkwọ ahụ ga-ejidesi ike na electromagnet 1. A na-eme ka ehulata site na ịtụgharị 41 na-atụgharị site na nkuku a chọrọ na ọkụ ahụ wee laghachi n'ọnọdụ ahụ. egosiri na FIGS.£ na 2 iji mebie eriri igwe 9.

Enwere ike ibugharị mpempe akwụkwọ ahụ ma ọ bụrụ na achọrọ ya ma nwee ike ịmegharị ọzọ.

Na FIG.1 otu n'ime ndị na-eche nche 71 na-egosi na elec tromagnet na mpempe akwụkwọ ígwè 84 nke agbagoro na 86 na 87 na-egosikwa.

Iji jiri ngwá ọrụ dị ka demagnetizer, a na-atụgharị 22 na njedebe 26 na 27,

Ngwá ọrụ a kọwara n'elu nwere ọtụtụ uru n'ime ya bụ na akụkụ igbe nwere ike ịme ngwa ngwa site na mpempe akwụkwọ;ogologo nke mpịachi na-ejedebeghị na ogologo nke ngwá ọrụ dị ka mpempe akwụkwọ nwere ike ịga n'ihu na ngwá ọrụ na-ehulata mgbe ọ bụla n'ihu;Enwere ike ịmepụta ngalaba mechiri emechi kpamkpam site na mpempe akwụkwọ;Enwere ike itinye ngwá ọrụ ahụ na bench ka ọ ghara ịnọ n'elu oche oche ọ bụla ma nwee ike ịdakwasị onwe ya na mkpụrụ ferromagnetic ọ bụla;a na-eme ngwa ngwa ngwa ngwa, ngwá ọrụ ahụ dị mfe ma dị ngwa iji; ọ dịghị mgbanwe ọ bụla achọrọ iji nabata ọkpụrụkpụ nke mpempe akwụkwọ dị iche iche;ngwá ọrụ ahụ nwere ike ịkwado ya na ngwá ọrụ ọzọ dị otú ahụ iji mee ka ogologo ya dị okpukpu abụọ.E gosipụtara nhazi a na FIGS.9 na 10, ebe otu ụzọ X,Y nke ngwa ọrụ nke ihe a na-emepụta ugbu a ejikọtawo na njedebe na njedebe iji mụbaa elu ọrụ nke ọma.Ọzọkwa, hinges 51 ga-ewere ndị agha na-ehulata na-enweghị ihe mgbochi na-ehulata n'ihi na ha anaghị arụ ọrụ n'elu ụgbọ elu kwuru.N'akụkụ a, a na-ewere ike na-ehulata ma iko 52 na pin 53. Karịsịa, ọ dị mkpa iburu n'obi na 51 ejedebeghị ka etinye ya na njedebe nke okporo osisi 7 na beam 41.

Ọ bụrụ na achọrọ, enwere ike ịwepụ osisi 41 ahụ site na ogwe osisi 7 site na ịtụgharị ya 180 ° site na ọnọdụ egosiri na FIGS.1 na 2.

Otu ihe owuwu nke ngwá ọrụ a kọwara n'elu nwere ogologo 600 mm, ịdị arọ nke 20 n'arọ.(anaghị agụnye ndị na-edebe ihe), eriri igwe kpụrụ site na waya ọla kọpa 22 na ịdị kilogram 2.4., Arụ ọrụ na 240 volt, otu oge, cycles 50 kwa nkeji AC ọkọnọ wee rie, nwa oge, 4 amps.Ihe owuwu ahụ a kapịrị ọnụ nwere ike ijide ígwè mpempe akwụkwọ dị ihe dị ka tọn 4.

Enwere ike ime mgbanwe na mgbanwe na ngwa a kọwara n'elu.

N'otu mgbanwe ma ọ bụ mmegharị egosiri na FIG.4, 51 na-anọchi anya hinges 151 nke nwere iko 152 na ogwe osisi 7 na pm 153 nke bụ akụkụ nke beam 41. Ihe owuwu ahụ na-arụ ọrụ nke ọma ma ọ bụghị con sidered dị ka nke ọma dị ka hinges 51, yana, yana cups 52 tak ing Forces from shell 54, pin 53 also take force from shell 54. Tụkwasị na nke a, pin 153 na-adabere n'igbu ndị agha iji jide ya na iko 152.

Na mgbanwe ọzọ ma ọ bụ mmegharị egosiri na FIGS.5 na 6 a na-enye onye na-eche nche 78 na oghere 91 nke a na-eji efere 92 nwere mbelata 93 nwere ike ijikọta ya na onye nche 78 site na skru 94. Iji onye nche 78 na efere 92 a na-ewepụ ahụ 2 na nke ahụ. Enwere ike iji ihu 93 kpachaa mpempe akwụkwọ 95 dị ka egosiri na FIG.6.

Nhọrọ ọzọ na efere 92 bụ efere 96 nyere ya na ọkpọ 97 na efere 96 a nwere ike itinye ya n'otu aka ahụ ka ọ bụrụ onye na-elekọta 78. Iji mee ka ịkụ ọkpọ dị mfe ọ na-ahọrọ na a na-enye 98 n'osisi 7 (lee FIG. 3).

N'ime ngwá ọrụ a kọwara n'elu, egosiri 51 hinges dị ka ndị nwere akụkụ integral na pole 7 na beam 41 mana na omume, a na-ahọrọ hinges ndị dị iche iche arụpụtara nke a na-enweta ma chekwaa na reces ses na pole 7 na beam 41.

Enwere ike ịme mgbanwe na mgbanwe ndị ọzọ.Dịka ọmụmaatụ, enwere ike ịnye efere nke nwere ọnụ ọnụ maka itinye n'osisi 7 iji kwado ya na mbepụ ọnụ 93. The beam 41 nwere ike ịnwe ụzọ maka ịkwanye ọnwụ, dị ka ezumike n'ime ya maka ịnata ọnwụ, na-emegharị na co. rụọ ọrụ na ndị na-eche nche nwere udi nkwado.N'otu aka ahụ, okporo osisi 7 nwere ike ịnwe ụzọ maka ịkwanye ọnwụ, dị ka ezumike n'ime ya maka ịnata ọnwụ, na-eme ka ya na ndị na-eche nche na-enwe ụdị mmekọ ọnụ ma ọ bụ na-anwụ anwụ nke ihe mgbakwunye na-agbanye na beam 41.

Ọ bụrụ na achọrọ, otu ma ọ bụ karịa n'ime ndị na-eche nche nwere ike ịkwanye n'otu elu ka ọ dị mfe ịchọta mkpanaka ma ọ bụ warara n'okpuru.

Mkpesa ndị a bụ akụkụ nke mkpughe nke ngalaba nkọwa a.

M na-ekwu:

1. Ngwa maka ịgbagọ workpieces gụnyere na com bination:

eriri electromagnetic;

okporo osisi emegharịrị ka ọ bụrụ magnetized site na eriri igwe ma na-arụ ọrụ n'akụkụ akụkụ dị ka ihe na-akwado maka mpempe ọrụ;

onye na-echekwa ferromagnetic nwere ihu ma ọ bụ elu nke enwere ike ịmepụta workpiece, ma gbanwee ka edobe ya n'ọnọdụ na-arụ ọrụ, na-emegide ịgbagọ ma ọ bụ na-akpụ ike, kpamkpam site na ike ndọta na-ebilite site na ndọta ndọta emepụtara na ike nke eriri igwe kwuru. , na a ọrụ elu pụtara pivotable n'ihe banyere okporo osisi na-etinye ụgbọ elu nke kwuru na ọrụ elu pụtara ọ dịkarịa ala substantially n'otu ụgbọ elu dị ka akwado elu nke okporo osisi na substantially ọ dịghị akụkụ nke kwuru osisi ma ọ bụ kwuru ọrụ elu pụtara pro jecting na. otu akụkụ nke kwuru otu ụgbọ elu, na opera tive na-eji itinye ekwe ike na workpiece.

2.A ngwá ọrụ dị ka a na-ekwu na 1 na-agụnye ọnụ ọgụgụ nke ndị dị otú ahụ na-edebe nke dị iche iche size na / ma ọ bụ udi.

3.A ngwá ọrụ dị ka a na-azọrọ na 1 na gụnyere mgba ọkụ pụtara na ebe ọrụ n'elu pụtara bụ a elu nke a ahu nke pivotable n'ihe banyere okporo osisi si a mbụ ọnọdụ nke mgbanwe pụtara actuated na-eme ka eriri igwe de-energised. gaa n'ọkwa nke abụọ nke a na-eme ka mgba ọkụ na-eme ka ọ dị ike.

4.A ngwá ọrụ dị ka a na-azọrọ na 3, ebe kwuru ozu na-emi esịnede a ferromagnetic ihe na-n'ịnyịnya na okporo osisi nke ga-eleda anya n'ihu na energisation nke eriri igwe si kwuru nke abụọ ọnọdụ n'ebe kwuru mbụ ọnọdụ.

5.A ngwá ọrụ dị ka a na-azọrọ na 1, bụ ebe okporo osisi na-agụnye a planar elu inwe onu na ebe ọrụ elu bụ planar na-emegharị ka pivot banyere ihe axis dịkarịa ala substantially co-imerahụ na nsọtụ.

6.A ngwá ọrụ dị ka a na-azọrọ na 1, ebe a na-enye onye na-elekọta ya ụzọ emeghari ka ọ banye n'ime akụkụ ọrụ na mmasị nke onye na-elekọta ya na okporo osisi.

7.Ngwá ọrụ dị ka a na-ekwu na 1, yana gụnyere electri cal pụtara gụnyere ihe nrụzi emezigharị iji nye DC ugbu a na eriri igwe na n'ihu gụnyere mgba ọkụ pụtara emegharịrị iji jikọọ eriri igwe nhọrọ na rectifier ma ọ bụ na ọkọnọ AC.

8.A ngwá ọrụ dị ka a na-ekwu na nkwupụta 1 na njikọ na nkwado maka ngwá ọrụ;nkwado nke nwere ihe ferromagnetic nke akụrụngwa nwere ike itinye onwe ya site na mma ndọta n'ime ya.

9.A ngwá ọrụ dị ka na-azọrọ na 1, ebe osisi na-agụnye a planar surfoce nwere onu, ọrụ elu pụtara bụ a planar elu nke a ahu nke, n'otu ọnọdụ nke kwuru ahu, ụgha dịkarịa ala substantially na otu ụgbọelu dị ka. nke mbụ e kwuru n'elu planar, kwuru na ahu bụ pivotable banyere ihe axis dịkarịa ala substantially ejikọta ọnụ na kwuru n'ọnụ site a hinge compris ing a ezumike na kwuru osisi nwere a ọkara okirikiri concave udi transverse kwuru axis na a so na-ebu. site kwuru ahu nwere a ọkara okirikiri convexity transverse ka kwuru axis na natara na kwuru ezumike na ebe na kwuru ahu na kwuru ọnọdụ substantially ọ dịghị akụkụ nke okporo osisi, kwuru ma ọ bụ kwuru ozu oru n'otu akụkụ nke kwuru ụgbọ elu.

10.A ngwá ọrụ dị ka a na-ekwu na 9 na-agụnye a plu raality nke ndị dị otú ahụ hinges.

11. Ngwá ọrụ dị ka a na-ekwu na nkwupụta 10, bụ ebe ọ dịkarịa ala otu n'ime ihe ndị a na-ekwu na-agbanye site na nsọtụ nke ahụ kwuru.

12.A ngwá ọrụ dị ka na-azọrọ na 9, na gụnyere a hinge ntụtụ ebu site okporo osisi na-enwe a ọkara okirikiri con vexity transverse kwuru axis na natara na ezumike na kwuru so na-enwe a ọkara okirikiri concave udi na ebe substantially ọ dịghị. akụkụ nke ntụtụ kwuru n'otu akụkụ nke ụgbọ elu kwuru.

13.A ngwá ọrụ dị ka a na-azọrọ na 12 na gụnyere a plurality nke ndị dị otú ahụ hinges na ebe ọ dịkarịa ala otu n'ime kwuru hinges na-spaced si na nsọtụ nke ahụ kwuru.

14.A ngwá ọrụ na-ehulata workpieces gụnyere magnetizable okporo osisi pụtara maka na-akwado dịkarịa ala akụkụ

nke workpiece kwuru;

eriri igwe electromagnetic pụtara maka magnetizing kwuru na osisi pụtara;

ọrụ elu pụtara, pivotable n'ihe banyere kwuru okporo osisi pụtara, n'ihi na n'itinye ekwe ike na a ọrụ ibe enịmde na kwuru osisi pụtara kpamkpam site magnetik;na

ferromagnetic nche pụtara, inwe ebe megide nke a workpiece nwere ike kpụrụ, n'ihi na magneti cally retaining kwuru workpiece on kwuru osisi pụtara kpọmkwem megide ekwe ekwe ike etinyere kwuru workpiece site kwuru ọrụ elu pụtara.

15.Ngwongwo nke ebubo 14, ebe kwuru na mpaghara bụ nsọtụ nke kwuru echebe pụtara.

16.A ngwá ọrụ na-ehulata workpieces gụnyere

okporo osisi pụtara gụnyere mbara ala nke mbụ akọwapụtara n'akụkụ ya site na nsọtụ;

ọrụ elu pụtara inwe a abụọ planar elu na pivotable si a mbụ ọnọdụ na a abụọ position banyere axis dịkarịa ala substantially coincency na kwuru n'ọnụ, kwuru nke abụọ planar elu dina dịkarịa ala substantially na otu ụgbọelu dị ka kwuru mbụ planar elu mgbe kwuru ọrụ. elu pụtara bụ na kwuru na mbụ ọnọdụ, na-enweghị akụkụ nke kwuru na okporo osisi pụtara ma ọ bụ kwuru na ọrụ elu pụtara projecting

n'otu akụkụ nke kwuru ụgbọ elu, na-arụ ọrụ n'elu pụtara n'itinye ekwe ike ka a workpiece na kwuru osisi pụtara na kwuru na-arụ ọrụ n'elu pụtara mgbe kwuru na-arụ ọrụ n'elu pụtara na-akpali si kwuru mbụ position kwuru nke abụọ ọnọdụ;

ferromagnetic nche pụtara, inwe ihu ma ọ bụ sur ihu megide a workpiece nwere ike kpụrụ;na

magnetizing pụtara maka magnetizing kwuru na okporo osisi pụtara magnetically jide kwuru workpiece na kwuru na onye nche pụtara na-ekwu na osisi pụtara kpamkpam site mag netic ike kpọmkwem na-emegide ekwe ike etinyere kwuru workpiece site kwuru ọrụ elu pụtara.

17.Ngwongwo nkwuputa 16febe ọ dịghị akụkụ nke kwuru ngwá ọrụ ma e wezụga kwuru keeper pụtara bụ n'elu kwuru na mbụ planar sur ihu mgbe kwuru na ọrụ elu pụtara bụ na kwuru na mbụ position.

18.Tool nke na-azọrọ 17, ebe a plurality nke kwuru ngwá ọrụ nwere ike na njedebe-na-ọgwụgwụ kwekọọ na n'ụzọ dị irè mụbaa ọrụ elu.

Oge nzipu: Ọktoba 11-2022